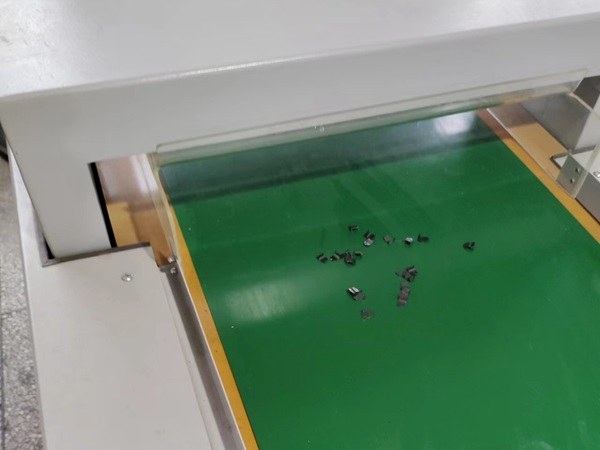

Needle detector refers to the use of electromagnetic principle to detect the iron (nickel) content per unit area of products. If the plating is not non lat, you must not pass the inspection needle. High precision copper products, environmental protection and nickel free surface treatment, can pass the inspection needle. In the classification of copper materials, there are 62 / 65 / 68 (68 copper in the market, which is actually 65 high-precision copper). Sometimes even the manufacturer uses some copper materials recycled from waste materials, of which the iron content is high, so it cannot pass the inspection needle.

To sum up, the requirement of environmental protection for button products means that the finished products do not contain azo, lead, nickel, etc. the passing inspection needle means that the products can pass the inspection of the needle detector. The popular saying is: environmental protection products may not pass the needle inspection, but the products that pass the needle inspection must be environmental protection. Of course, as an environmental friendly metal button, its own material can not be ignored. If we use excessive iron to make buttons, its material can not be made without plating, so it is impossible to make environmental friendly metal buttons.

Alloy buttons can also be electroplated for environmental protection, but they may not pass through the needle inspection machine. Because the raw material itself contains nickel of certain composition, especially the buttons with larger volume, that is to say, the larger the volume of alloy buttons, the more difficult it is for the needle inspection machine.